Use of Drones in Different Industries

In terms of the technological advancement that the aviation industry has seen in the current decade, the drone industry has experienced a significant improvement in design and application from how the military has used it in its surveillance operation into how other industries such as agriculture, photography, and logistics have used drones to their advantage in improving their business operations.

In terms of the technological advancement that the aviation industry has seen in the current decade, the drone industry has experienced a significant improvement in design and application from how the military has used it in its surveillance operation into how other industries such as agriculture, photography, and logistics have used drones to their advantage in improving their business operations.

As the current design and capability of drones available in the market continuously improve, the industry and businesses where its application looks feasible also continuously grow. Currently, industries that have looked to use drones in their operations include the following:

● Agriculture – The use of drones in the agriculture industry gave farmers and farm operators the advantage of efficiently monitoring their crops and livestock. Recent advances in drone design and capability enabled the use of drones in the aerial application of fertilizers and insecticides. Also, with the use of advanced imagery, farmers have been able to monitor crop health and the possibilities of irrigation problems and pests.

This industry will certainly look for improvement in drone capability in terms of increasing its payload to handle more volume of fertilizers and improve the onboard imaging capability to capture crop and livestock data that the naked-eye are not able to do.

● Photography – Seen before as the game-changer in the photography industry, drones have enabled both professional photographers and hobby-level operators to produce images and videos that improve the cinematic value of their products.

This industry continues to grow as the demand by hobby-level operators increases and the price of drones in the market becomes more affordable.

● Logistics – Envisioned by Amazon to improve its customer service by decreasing its delivery time to customers, the use of drones in the logistics industry enables seamless delivery as drones can simply bypass land traffic by simply flying over them.

The use of drones in the Logistics industry proves to be promising as there is a current need from logistic organizations to further improve the drone design and capability. We expect that the drones to be used in this industry will further improve in design to accommodate larger and heavier parcels while at the same time increase its travel distance.

● Disaster Response – Drones have provided emergency responders the capability to inspect accident sites that may be deemed dangerous for humans to enter.

In the future, we expect drones to be able to conduct maritime search and rescue operations wherein an increased operating range is important. Drones that are also designed to operate in poor environmental conditions and treacherous terrain will be considered a game-changer.

● Law Enforcement and Other Government Agencies – By simply considering drones as an eye on the sky, we can easily see the reason why Law Enforcers and other Government Agencies have increased their dependence on this technology.

In the future, we can see drones having the capability of facial recognition as what current state-of-the-art CCTV has been designed too.

● Air Travel – The application of drones in the aviation industry specifically to transport passengers and a large amount of cargo has a lot of hurdles to overcome.

First, the technology needs more improvement to ensure that it can duplicate the decision making of what an experienced and coveted airline pilot would possess. This task would also need education and information dissemination to prospective passengers in helping them overcome any doubts in the safety of a flying aircraft without a pilot on-board.

Second, the cost of developing and maintaining such technology must become more affordable to entice prospective buyers and operators in placing orders.

Market Statistics

As drone design and capability continuously improve, the industries where it can be possibly used is continuously growing.

As drone design and capability continuously improve, the industries where it can be possibly used is continuously growing.

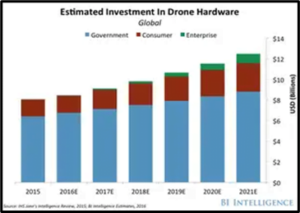

Based on the latest statistics reported by Business Insider, the estimated 2019 figure of the investments made on drone hardware stood at around USD 11 Billion. A huge portion of this investment came to form by government purchases through what we perceived are from government agencies and military purposes.

Estimates also show that the current trend is likely to continue upwards as estimates predict an increase of investment of more than USD 12 Billion come 2021. Interestingly and which further supports our analysis, the group with the next largest market share to the government for drones are the basic consumers which consists of enthusiasts and non-professional or small-time videographers. We believe that the bulk of the amount is purchases made by individuals in retail.

Current Headwinds

However, this technology and its access to the US market comes with its own problem. In compliance with the National Defense Authorization Act for Fiscal Year 2020 which was signed by President Donald Trump and made into law on December 12, 2019, any U.S. Government Agency is banned to purchase or operate existing drones in their inventory that has been manufactured in China. The ban includes spare parts that may be either used to repair or assemble any drones in any U.S. Agency’s drone inventory.

However, this technology and its access to the US market comes with its own problem. In compliance with the National Defense Authorization Act for Fiscal Year 2020 which was signed by President Donald Trump and made into law on December 12, 2019, any U.S. Government Agency is banned to purchase or operate existing drones in their inventory that has been manufactured in China. The ban includes spare parts that may be either used to repair or assemble any drones in any U.S. Agency’s drone inventory.

Although the law stated that the purchase of drones and its spare parts are prohibited against what the U.S. Government calls as “Covered Foreign Entity”, it is obvious that the law is targeting Chinese made products which are a center of concern in respect to the U.S. national security. Reports say that Chinese drone manufacturers with a special focus on the state-backed DJI use its product with the help of its built-in app to spy on private and government users by collecting their personal information data and flight logs.

This law does not cover private individuals and business owners from purchasing Chinese made drones. Interestingly, the U.S. Government responded to this by including drone products on the additional tariffs imposed by President Trump. This resulted in the leading drone manufacturer in the world which is surprisingly the Communist Party of China-backed DJI to increase the prices of its product sold in the U.S.

Who Will Stand to Benefit

From a separate point of view, the tariffs imposed on China-made products can also be considered a help to local US drone manufacturers that are struggling to compete with the ridiculously cheap price China has been supplying.

Perhaps, if there is someone who would truly benefit amidst this whole fiasco, it is the real “Made in USA” drones. According to the Federal Trade Commission, “Made in America” pertains to products that have all been virtually made in the USA. This includes all the significant parts, processing, and labor that must be all sourced within the USA.

The current notable “Made in the USA” drone manufacturers include the following:

● Auterion – Auterion’s platform is the only cloud-enabled solution that smoothly integrates the data captured by your drones into your existing workflows, by linking software on the drone and ground station with advanced cloud management tools.

● Skydio – Skydio Autonomy™ has the skills of an expert pilot. It uses AI to understand the world around it and predict the future to make intelligent decisions. Skydio drones can fly themselves through the most demanding tasks or keep you safe from obstacles when you want to take control.

● Altavian – Altavian is one of the few American-based companies that still designs and produces their systems in-house. Altavian blends its experience in the commercial and defense markets to create open, modular systems.

● InstantEye Robotics – Boasts of developing advanced autonomous algorithms for additional payloads and functionality that specifically target very low size, weight, power, and cost (SWaP-C) hardware. Ultimately, this allows the overall vehicle to be smaller, lighter, and faster, which translates into better wind performance and longer flight times.

● Draganfly – Draganfly has more than 20 years of experience designing and manufacturing professional drones for military, public safety, energy, agriculture, and insurance.

● Impossible Aerospace – Impossible Aerospace builds high-performance electric aircraft that save lives. Founded in 2016 by former Tesla engineer Spencer Gore, the company unveiled its US-1 aircraft in 2018, unique for its long endurance and US origin. The company is backed by Bessemer Venture Partners, Eclipse Venture, and Airbus Ventures.

● TerraView – Focused on the application of drones in agriculture with a product whose strengths goes into the use of drones in vineyards.

● UAVAmerica – UAV-America provides custom and off-the-shelf aerial systems (drones, UAV, UAS, sUAS) for both complex and routine challenges. UAVA products limit exposure to cyber vulnerabilities. Their products are closed systems and never require an internet connection.

● AgEagle Aerial Systems – AgEagle designs, manufactures, distributes and supports a diverse line of advanced, high performance, “tractor tough,” precision drones capable of capturing thousands of ultra-high resolution images and producing actionable intelligence that get quantifiable results.

Even with the current tariff, we have compared the drone prices from different manufacturers that are readily available on the web and have seen that the best selling China-made DJI drone is still cheaper compared to the other U.S. made drones. It is important to note that the DJI Mavic Air 2 drone is designed to be sold for enthusiasts while U.S.-made drones are designed for more specialized applications such as law enforcement, surveillance, and inspection.

Going back to the existing market demography, the second-largest market for drone products are consumers which is where China made DJI has its advantage because of its cheaper price and simple operation and control. While the design of U.S. based manufacturers is considered more advanced, its target market is for business organizations and enterprises which have the smallest share of the drone market.

We can see that the U.S.-based manufacturers will eventually gain support as the current administration has banned the use of China-made drones on any U.S. Government Agency which will surely pave the way for U.S. based manufacturers to win government contracts and sales.

Another potential business strategy that U.S. based manufacturers can look into is designing a low-end drone product which can rival the price point of China-made drones while at the same time providing an off the shelf product that is simple to use and operate.

Market Decisions

Considering how untapped and ready for expansion the drone industry is in the U.S. Market, time will only tell when the next “Amazon”, “Google” or “Apple” of the drone industry will eventually take center stage.

From what we are seeing now, the US government through its efforts by passing laws and tariffs against the “competitor-killing price” scheme of the China Communist Party-backed business ultimately helps American made products to eventually develop and in the long term lower their price to be competitive while still leading the industry with state-of-the-art ideas and innovation.

For this whole scheme of things to play out in U.S. interests, the public through its spending behavior must start to rally and support local businesses. Again, the fruit is ripe and it is for anyone to take. If you’re looking for your next “A Player” in the drone market, reach out to Craig now.

In terms of the technological advancement that the aviation industry has seen in the current decade, the drone industry has experienced a significant improvement in design and application from how the military has used it in its surveillance operation into how other industries such as agriculture, photography, and logistics have used drones to their advantage in improving their business operations.

In terms of the technological advancement that the aviation industry has seen in the current decade, the drone industry has experienced a significant improvement in design and application from how the military has used it in its surveillance operation into how other industries such as agriculture, photography, and logistics have used drones to their advantage in improving their business operations. As drone design and capability continuously improve, the industries where it can be possibly used is continuously growing.

As drone design and capability continuously improve, the industries where it can be possibly used is continuously growing. However, this technology and its access to the US market comes with its own problem. In compliance with the National Defense Authorization Act for Fiscal Year 2020 which was signed by President Donald Trump and made into law on December 12, 2019, any U.S. Government Agency is banned to purchase or operate existing drones in their inventory that has been manufactured in China. The ban includes spare parts that may be either used to repair or assemble any drones in any U.S. Agency’s drone inventory.

However, this technology and its access to the US market comes with its own problem. In compliance with the National Defense Authorization Act for Fiscal Year 2020 which was signed by President Donald Trump and made into law on December 12, 2019, any U.S. Government Agency is banned to purchase or operate existing drones in their inventory that has been manufactured in China. The ban includes spare parts that may be either used to repair or assemble any drones in any U.S. Agency’s drone inventory.

Cloaking technologies which are already underway and anti-gravity. Conspiracy theory websites are full of stories of government work on anti-gravy devices but have little in the way of concrete proof of the claims.

Cloaking technologies which are already underway and anti-gravity. Conspiracy theory websites are full of stories of government work on anti-gravy devices but have little in the way of concrete proof of the claims.

That’s how NASA brought the Apollo 13 crew home. Smart people used intelligent methods to limit the power consumption in the spacecraft to direct energy to where it was most needed. Many people credit the contracting firm Kepner-Tregoe and their problem analysis method for saving the astronauts. And who hasn’t seen the movie “Apollo 13” directed by Ron Howard?

That’s how NASA brought the Apollo 13 crew home. Smart people used intelligent methods to limit the power consumption in the spacecraft to direct energy to where it was most needed. Many people credit the contracting firm Kepner-Tregoe and their problem analysis method for saving the astronauts. And who hasn’t seen the movie “Apollo 13” directed by Ron Howard?

Jump forward several years, and now we have streaming video, movies and more coming in over wireless and data from cellular providers. For the airline industry, this is an absolute goldmine in IFEC profit margins.

Jump forward several years, and now we have streaming video, movies and more coming in over wireless and data from cellular providers. For the airline industry, this is an absolute goldmine in IFEC profit margins.